Custom-Engineered Power Generation Solutions

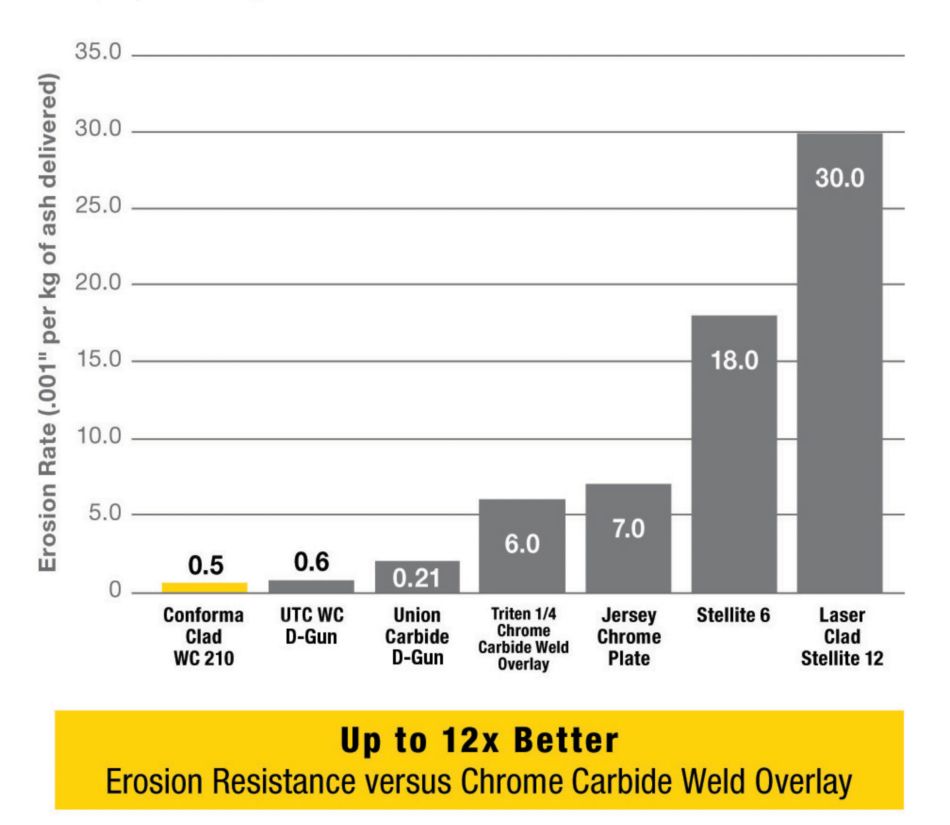

Kennametal Conforma Clad™ offers custom-engineered power generation solutions for coal-fired or biomass power plants. Our cladding formulas are designed to protect equipment from multiple modes of wear including abrasion, corrosion, erosion or all three combined.

This proprietary cladding technology can be applied to a broad range of applications including:

- Fan blades

- Fan blade liners

- Boiler tubes and tube shields

- Burner components

- Screens

?hei=300)

?hei=300)

?hei=300)

?hei=300)